Training Courses

Fundamentals of Lean Manufacturing

Fundamentals of Lean Manufacturing

Fundamentals of Lean Manufacturing

This material can be covered in 4 hour or 8 hour format, depending on the audience and the depth of knowledge desired. Hands-on simulations with classroom presentation drives home content and principles.

Value Stream Mapping

Fundamentals of Lean Manufacturing

Fundamentals of Lean Manufacturing

Do you know what REALLY goes on inside your facility? Most companies do not. This training will let you identify the way things are currently flowing, and identify bottlenecks and improvement opportunities.

5S

Fundamentals of Lean Manufacturing

Single Minute Exchange of Dies (SMED)

5S is more than just cleaning. This training will take you through the step by step process to improve your operations by organizing and laying out your processes in an efficient manner.

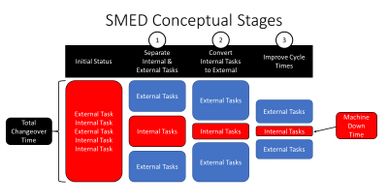

Single Minute Exchange of Dies (SMED)

Single Minute Exchange of Dies (SMED)

Single Minute Exchange of Dies (SMED)

Small batches are vital to achieving continuous flow. SMED (aka Quick Changeover) training will let you keep your equipment running by minimizing downtime between tooling changes.

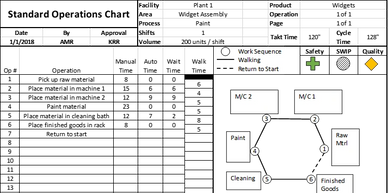

Standardized Work

Single Minute Exchange of Dies (SMED)

A3 Problem Solving

Reducing variation is critical for providing consistent quality and efficient operations. Standardized Work Training will allow your company to develop thorough best practices to keep your customers happy.

A3 Problem Solving

Single Minute Exchange of Dies (SMED)

A3 Problem Solving

Does your organization struggle with aligning improvement activities with company goals and metrics? A3 / 8 Step Problem Solving will help your employees align leadership vision with actionable improvements on the shop floor.

Custom training available upon request

If your company is facing a specific challenge and would like custom training developed, we can do that too. Let us know your needs and we will develop a plan to help.